Breaking the Fashion Waste Cycle

In a world dominated by fast fashion and consumerism, the staggering issue of clothing waste has emerged as a pressing global concern. In an attempt to regulate the industry, the ministry of infrastructure and water management in the Netherlands has taken a groundbreaking step towards tackling the growing problem of textiles by introducing Extended Producer Responsibility (EPR) regulation for textiles. This legislation, which came into effect on the 1st of July of this year, aims to hold manufacturers accountable for the entire lifecycle of their products, encouraging them to adopt sustainable practices and reduce the environmental impact of the fashion industry.

Every year, 238,000,000 kg of textiles are discarded in the Netherlands alone. About 53% of this is still perfectly wearable.

Traditionally, the burden of clothing waste has largely fallen on consumers. The “buy and discard” mentality promoted by the fashion industry has fuelled the cycle of overconsumption, exacerbating the waste problem. However, the paradigm is shifting, and the spotlight is now on manufacturers to take responsibility for the environmental impact of their products. According to the Ellen Macarthur foundation, every second, the equivalent of one garbage truck of textiles is landfilled or burned and an estimated $500bn value is lost every year due to clothing that’s barely worn and rarely recycled. The resource-intensive processes involved in textile production, coupled with the excessive use of non-renewable materials and the sheer volume of new garments being produced, have resulted in an inefficient and wasteful textile industry that’s negatively impacted people and the planet.

In this article, we delve into the issue of clothing waste, highlight a groundbreaking project we’re working on with a fashion pioneer centred around circularity and explore how the Netherlands’ EPR regulation is poised to revolutionise the way we produce and consume fashion.

Fashioning a Greener Future: The Netherlands’ Textile EPR Initiative

The Dutch government has taken a bold step to address clothing waste through the Extended Producer Responsibility (EPR) regulation for textiles. This pioneering legislation requires clothing manufacturers and importers to be accountable for their products throughout their entire lifecycle. Under this framework, companies will be responsible for the collection, sorting, and recycling of used textiles, pushing them to adopt more sustainable and circular business models.

Previously, textile products could freely enter the Netherlands without any consideration for their post-use fate. However, with the introduction of the Textile-EPR regulation, a comprehensive approach is being implemented to address the environmental impact of textiles. The Textile-EPR regulation applies to a wide range of textile products including household linens and it mandates that producers and importers operating in the Dutch market contribute to an innovation fund by paying a fee per product. This fund aims to stimulate sustainable and circular initiatives and business models within the industry.

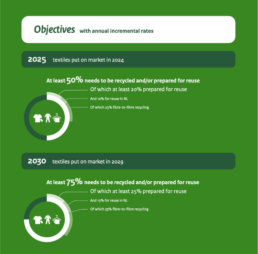

Under the Extended Producer Responsibility (EPR) Textile Decree, manufacturers and importers will be obliged to establish easily accessible and cost-free collection points across the Netherlands, allowing consumers to drop off their textile products at any location and time. Additionally, they are required to demonstrate the proper management of the collected textile waste, either by providing evidence of recycling processes or by showcasing appropriate disposal methods. Another important requirement of the textile EPR is that by 2024, all clothing retailers will have to declare how much clothing they sold in the Netherlands in the previous year.

The EPR regulation is a game-changer that is set to disrupt the fashion industry’s conventional practices. Its comprehensive approach means that manufacturers are now incentivized to design products with longevity and recyclability in mind. The emphasis on circular economy principles will drive innovation, as businesses explore new ways to reuse and repurpose textiles to minimise waste.

While the EPR regulation holds manufacturers accountable, it also empowers consumers to make more conscious choices. Through enhanced collection and recycling systems, the burden of textile disposal is lifted from consumers, who can now confidently donate or return used clothing to designated collection points.

Kiki Hagen on the impact of the new textile EPR for brands and citizens

We spoke to Kiki Hagen, a Dutch politician of the Democrats 66 party and a big advocate for government intervention to regulate the fashion industry. She shared some insights into this new textile EPR regulation.

In practice, Hagen tells us, “The principle of extended producer responsibility is that a fund has been created for all brands, small and large, and the contribution is equal. You have to contribute per kilo of what you put on the market, and that is then used for the collection and recycling at the back. After citizens hand in the items, municipalities receive a fee to process it.”

When asked about the feasibility of garment recycling with the existing technologies she explained “The technology is available, but the scale is not yet there to fully provide the recycled material needed, it will require more demand, but also more collected textiles of good quality. The EPR regulations will in any case ensure that demand is created and therefore allow the recycling technology to be scaled up.. so what we will hopefully see is a higher recycled material base for clothing.”

The regulations ensure that producers adhere to the targets. There are currently no sanctions but it’s expected that companies work together and for big and small brands to collaborate to make the entire fashion supply chain more sustainable. Citizens will also indirectly benefit from the more organised collection of clothing and hopefully reduced waste tax to their municipality, as it would be paid for by the producers.

"The good thing about the EPR is that all players sit together at the table. I always call on the sustainable pioneers to sit down together and represent each other, because that way you can also compete against those very big players”. Kiki Hagen

HIGH HOPES: A documentary unveiling the power of collaboration and boundless optimism in the fight against textile waste

As a campaign agency committed to driving change in fashion by highlighting the important work of fashion pioneers, we’re proud to work with fashion companies that are working to reduce waste and embrace circularity. One enterprise at the forefront of this movement is The Swapshop.

The Swapshop is on a mission to reduce textile waste and make the fashion industry more circular. With their innovative clothing swap concept, they’ve already made a significant impact. Instead of buying new garments, The Swapshop invites customers to exchange their clothing, offering a sustainable alternative to fast fashion. With over 7,000 registered customers and more than 45,000 items finding new owners in the past 2 years alone, they’ve already saved a staggering 27 million liters of water and prevented 74,000 kg of CO2 emissions.

With their unique approach to tackling waste under the EPR legislation, they prove that there’s a thriving business model in the collection, reuse, and recycling of textiles. Their vision of a circular textile industry caught the attention of policymakers, making them frontrunners in advocating for a circular textile industry during a significant round table discussion at the House of Representatives.

Every year, The Swapshop has a surplus of 20,000 non-swappable clothing items, a number set to grow with the expansion of their franchise formula. Unfazed by the challenge, Laura Suijkerbuijk and Monique Drent, the visionary entrepreneurs behind The Swapshop, alongside their chain partners, are developing a circular product line from this surplus. They’re breathing new life into discarded fabrics, recycling, spinning, weaving, and manufacturing right in the Netherlands. And their first product to hit the market? Introducing ‘The Puffer,’ a revolutionary circular laptop sleeve crafted from over 70% recycled cotton and designed to be 100% recyclable. They’ve even conducted a comprehensive Life Cycle Assessment to measure and mitigate the environmental impact of ‘The Puffer’, emphasising their commitment to transparency and accountability.

Founders Laura and Monique firmly believe in the power of collaboration, making it a cornerstone of their approach. Enter the HIGH HOPES campaign, designed to inspire everyone from consumers to experts to actively contribute to the circular textile industry. The Swapshop will further inspire the world with a captivating short documentary, created in collaboration with MUMSTER, which will be unveiled during the Dutch Sustainable Fashion Week on 6 October. This documentary sheds light on their relentless pursuit of a circular solution for the textile surplus, an inspiring journey filled with determination and creativity.

We’re thrilled to be part of this incredible movement by producing the inspiring documentary HIGH HOPES, which takes you behind the scenes with Monique and Laura as they encounter towering mountains of textile waste. Witness their determination and boundless optimism as they encounter challenges head-on, discovering innovative solutions and forging partnerships with experts who share their passion. You’re invited to the grand premiere event on 6 October at our brand-new office, The house of fashion pioneers, where we’ll celebrate this transformative initiative.

It will be an extraordinary combination of sustainability, style, and the unstoppable force of collective action. The Swapshop is more than just a brand; it’s a movement that dares to dream big, leading us towards a brighter and greener future. Join us on this incredible journey, where together, with HIGH HOPES, we’ll conquer the textile waste mountains and make a lasting impact on our planet.

Related Posts

December 18, 2023

The True Impact of Vegan Handbags: How Lisa Marin’s life cycle analysis proves their products are better for the planet than (faux) leather alternatives.

Handbags are one of the most prominent…

September 1, 2023

A Tool for Change: Unveiling the Visionaries of Sustainable Fashion

In a world dominated by fast fashion…

August 16, 2023

Driving Change in the Fashion Industry: Lessons from the Copenhagen Global Fashion Summit 2023

The fashion industry has long been…